About Pressure Filters

Pressure filters rely on a porous media to retain solids from high concentration slurries and use the feed pressure of the pump to "squeeze" the free water from the resulting sludge cake. The cloth retains the solids and the cake removes more and finer solids, resulting in a better, more efficient filter.

Pressure filters rely on a porous media to retain solids from high concentration slurries and use the feed pressure of the pump to "squeeze" the free water from the resulting sludge cake. The cloth retains the solids and the cake removes more and finer solids, resulting in a better, more efficient filter.

These filters come in a variety of configurations including flat bed, plate and frame, recessed plate, pressure leaf and tubular back-pulse designs. They are used for solids removal, solids recovery, fluid recycling and solids dewatering.

Pressure filters clarify process fluids, clean wastewater and reduce the cost of hauling fluids or wet slurries off-site for disposal.

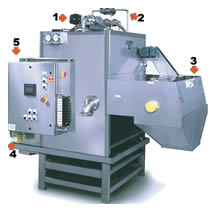

PAPSCO Pressure Filters Features:

- Filtration down to 0.5 Micron

- High filtrate quality

- Variety of filter medias available

- Gasketed or non-gasketed plates

- Full range of automation and controls

- Automatic pump controls

- Cake washing features

- Up to 95% solids cake dryness

- Engineered solutions

- Turnkey systems, including filter aid and bodyfeed

Examples of Pressure Filters Applications:

- Grinding and honing fluid recycling

- Wastewater treatment

- Metal hydroxides dewatering

- Dyes and pigments

- Zinc phosphate sludge

- Metals recovery

- Clays and ceramics dewatering

- Chemical processing

- Rolling mill waste

- Beverage clarification

- Wine and juice solids filtration

- Waste sludge dewatering

For more product details or to get online assistance in choosing the right solution for your filtration application:

Request a Quote or Information:

Connect with us today and talk to a helpfull representative to get answers to your questions.